Aotto Electric Heavy-Duty Trackless Cart: 10T–200T Intelligent Material Handling Solution

How to balance heavy payloads with pinpoint accuracy in die handling? Aotto Electric Heavy-Duty Trackless Cart delivers an efficient solution, driving smart workshop upgrades.

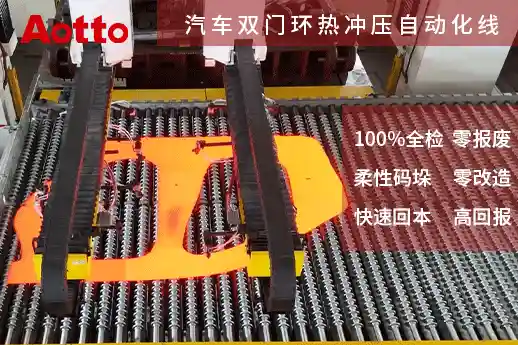

Aotto's Hot Forming Solution: Quality Inspection + Auto-Racking for Door Ring

Recently, Aotto has successfully delivered a 2000T double door ring hot forming line for a leading automotive parts manufacturer. This line integrates a quality inspection system and automatic racking system, delivering a comprehensive hot forming solution.

Stamping Line Retrofit Case: Aotto Upgrades Gestamp UK in 14 Days

With challenges of overseas existing line updating, Aotto shows the strong abilities of perfect delivery. For Gestamp Llanelli plant L9 updating line, there are many issues such as the equipment are old, and the working efficiency is low. Totally 14 days, Aotto team are successfully delivered a good job with 7 days to replace the robot and update the control system, which makes a showcase project for cold stamping line updating and makes a high praise from the client: “Professional delivery beyond expectations.”

Aotto Engages with Leading European Automotive Manufacturers on Strategic Collaboration

From April 7 to 12, 2025, a delegation led by Puxuan He, Deputy General Manager of Aotto, visited several leading European automotive and equipment manufacturers. The exchange fostered consensus on innovation, technical sharing, and mutual success, enabling advanced intelligent equipment solutions for global customers.

Aotto at Hannover Messe 2025 | Moving Towards Global Market with Innovation Drive

From March 31 to April 4, the Hannover Messe 2025 was successfully held in Germany. Aotto proudly took part in this world-renowned industrial fair, showcasing a lineup of innovative solutions while engaging with global industry experts, customers, and partners. Through this platform, Aotto demonstrated its growing technological strength and market potential in automation, industrial safety, and robotic end-effectors.

Benteler Delegation Visits Aotto for Strategic Collaboration Discussions

Recently, a delegation from Benteler, a globally renowned automotive parts manufacturer, visited Aotto to assess its technological capabilities, product quality, and production capacity, with a view to establishing future collaboration.

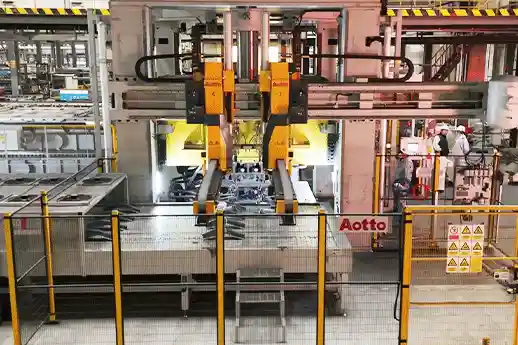

Aotto Supports Faway Benteler: Hot Forming Line Achieves 5.2 SPM

Aotto has supplied Faway-Benteler Automotive Components (Tianjin) Co., Ltd. with a hot forming line, enhancing production efficiency and product qualityto meet market demands and strengthen competitiveness.

Aotto Delivers Hot Stamping Line for FAW Huaxiang's Double Door Ring Project: First Piece Off the Line

Aotto has delivered the hot stamping line for FAW Huaxiang’s double door ring project, supporting its goal of becoming a leading lightweight vehicle body technology company in China and advancing lightweight body technology.

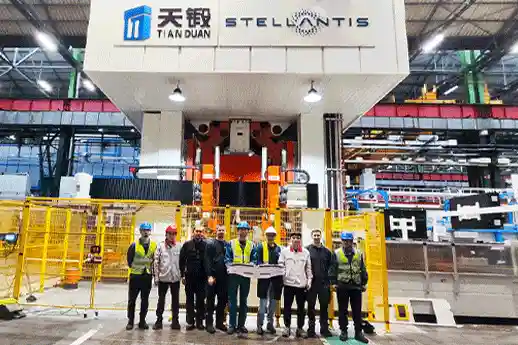

Joint Success: Aotto & Tianduan successfully delivered hot forming line to Stellantis!

On November 28th, Aotto, in cooperation with Tianjin Tianduan Press Co., Ltd. (hereinafter referred to as “ Tianduan”), has successfully completed the installation and commissioning of the 5th Hot Stamping Line for the VIGO plant of Stellantis, an international famous automobile manufacturer, and has successfully realized the first piece of trial production.

Aotto and Googoltech Signed Strategic Cooperation Agreement

On October 24th, Aotto (833748) and Googoltech(301510) held a strategic cooperation signing ceremony. GM Mr. Miao Jinzhong (representative of Aotto) and Marketing Director Mr. Bu Xianwei (representative of Googoltech) signed the agreement. Attendees included: Li Shanshan (Deputy Director of Changqing District Industry and Information Technology Bureau), He Ruilin (Chairman of Aotto), Wu Hong (Managing Director of Googoltech), and representatives of both parties.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.