Coil washer

Through cleaning, it will removes the dust and debris on the surface of steel sheet and evenly coats a layer of rust-proof oil film, enhancing lubrication during pressing, reducing the frequency of mold cleaning, improving the quality of sheet metal pressing, and optimizing the overall utilization rate of the production line.**Coil washer is mainly used in cleaning process before the leveling of the uncoiling line. After cleaning, it can effectively remove the impurities from the blank surface, prevent the impurities from contaminating the subsequent equipments such as leveling machine, reduce the maintenance cost, and improve the steel blank surface quality.

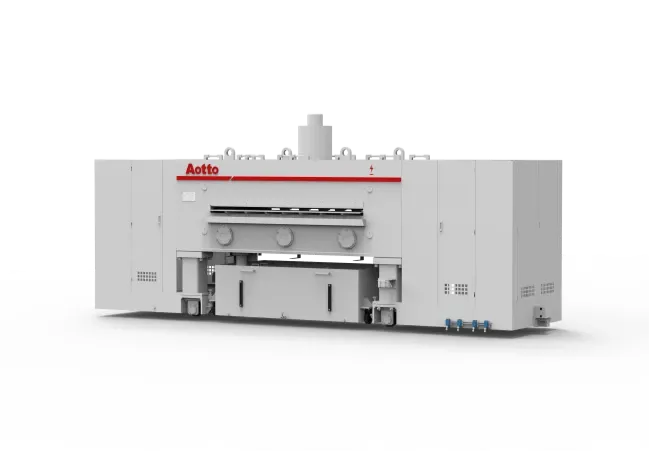

Laser blanking line washer

The laser blanking line washer is mainly used for the cleaning process before stacking. After cleaning, it can effectively remove impurities from the blank surface, welding slag produced by laser cutting, etc., significantly improving the blank surface quality.

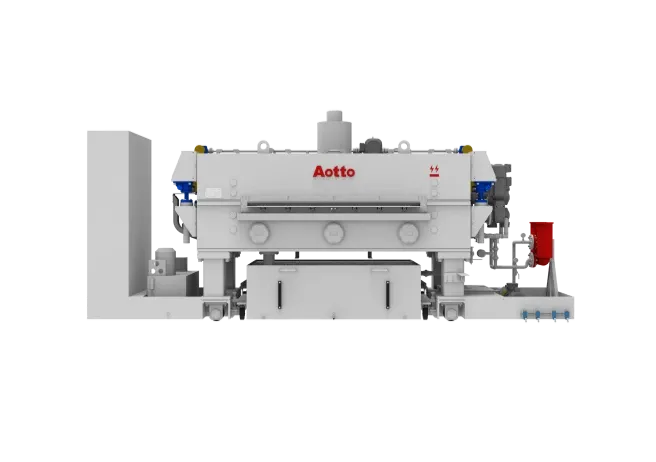

High speed stamping line washer

High speed stamping line washer is mainly used in cleaning process before steel blank stamping. After cleaning, it can effectively remove dust and foreign object from blank surface, but also can apply a layer of rust preventing oil film to its surface uniformly so as to increase lubricity during stamping, and to improve stamping parts quality.

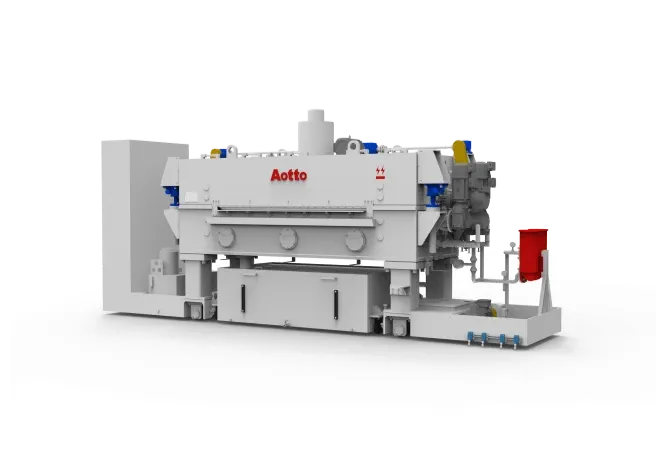

Blank washer

Blank washer is mainly used in cleaning process before steel blank stamping. After cleaning, it can effectively remove dust and foreign object from blank surface, but also can apply a layer of rust preventing oil film to its surface uniformly so as to increase lubricity during stamping, and to improve stamping parts quality.

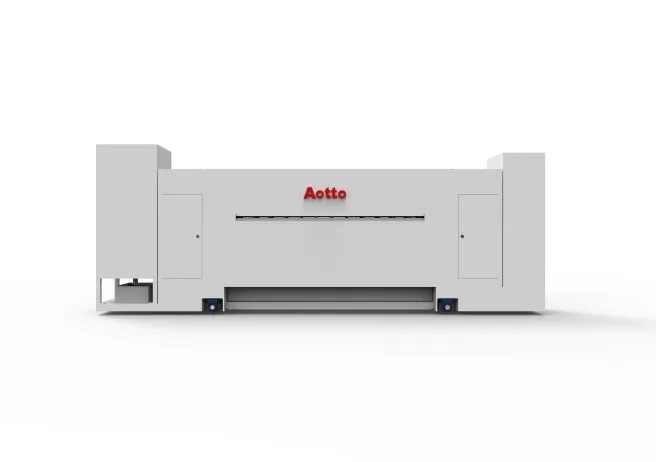

Cross brush washer

Blank washer is mainly used in cleaning process before steel blank stamping. After cleaning, it can effectively remove dust and foreign object from blank surface, but also can apply a layer of rust preventing oil film to its surface uniformly so as to increase lubricity during stamping, and to improve stamping parts quality.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.