Solution introduction

Aotto is one of the world’s leading suppliers of complete, turn-key production solutions for manufacturing press vehicle parts and one of the true pioneers in the industry. Since 2000, we have provided 150+ hot stamping lines for customers globally, which has given us unique experience.

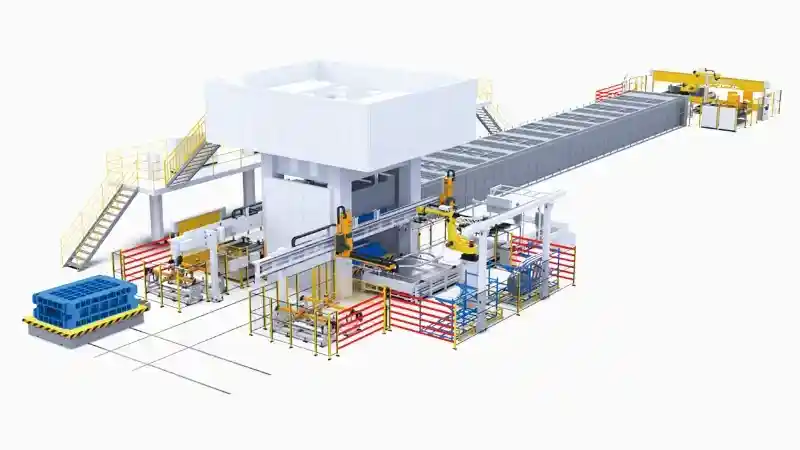

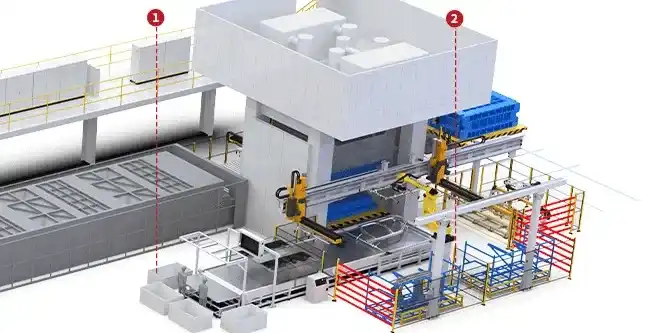

Structural display

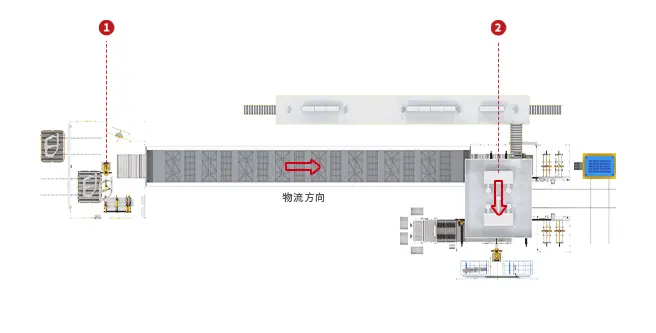

Flow Direction - L type

①

Robots or crossbar manipulator are available for the destacking unit.

Trolleys or fixed tables are available for sheet transportation, and the direction of off-line can be parallel or perpendicular to the flow direction of the heating furnace.

Trolleys or fixed tables are available for sheet transportation, and the direction of off-line can be parallel or perpendicular to the flow direction of the heating furnace.

②

Two motion modes: Transfer and Feeder.

The loading direction is perpendicular to the logistics direction of the heating furnace.

Chain conveyor: Unloading on the left/right side.

The loading direction is perpendicular to the logistics direction of the heating furnace.

Chain conveyor: Unloading on the left/right side.

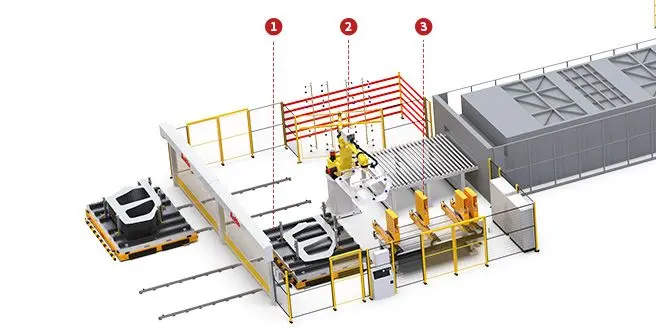

Flow Direction - linear type

① Marking: single or double side for mechanical marking or laser marking.

Gripper Option to select automatic tool changer.

Gripper Option to select automatic tool changer.

② Motion mode: Feeder.

Loading direction: parallel to the heating furnace flow direction.

Manipulator (both sides): Option to select automatic tool changer.

Loading direction: parallel to the heating furnace flow direction.

Manipulator (both sides): Option to select automatic tool changer.

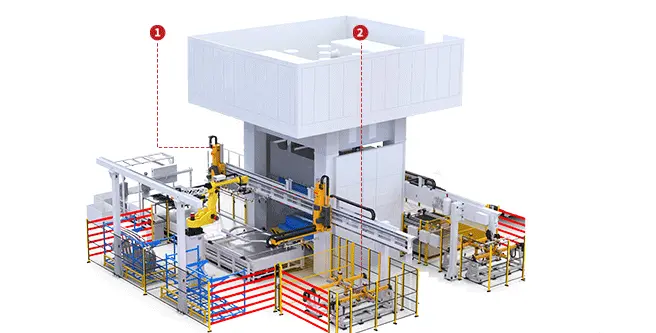

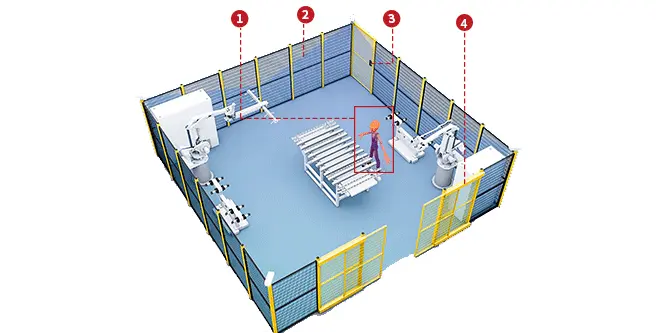

Inter-press Hot Stamping Transfer

①Loading and unloading manipulator and tooling

②Automatic tooling changer

Safety Guard Unit

①Visual security system

②Machine guarding fence

③Safety locks

④Safety doors

⑤Roller shutter doors

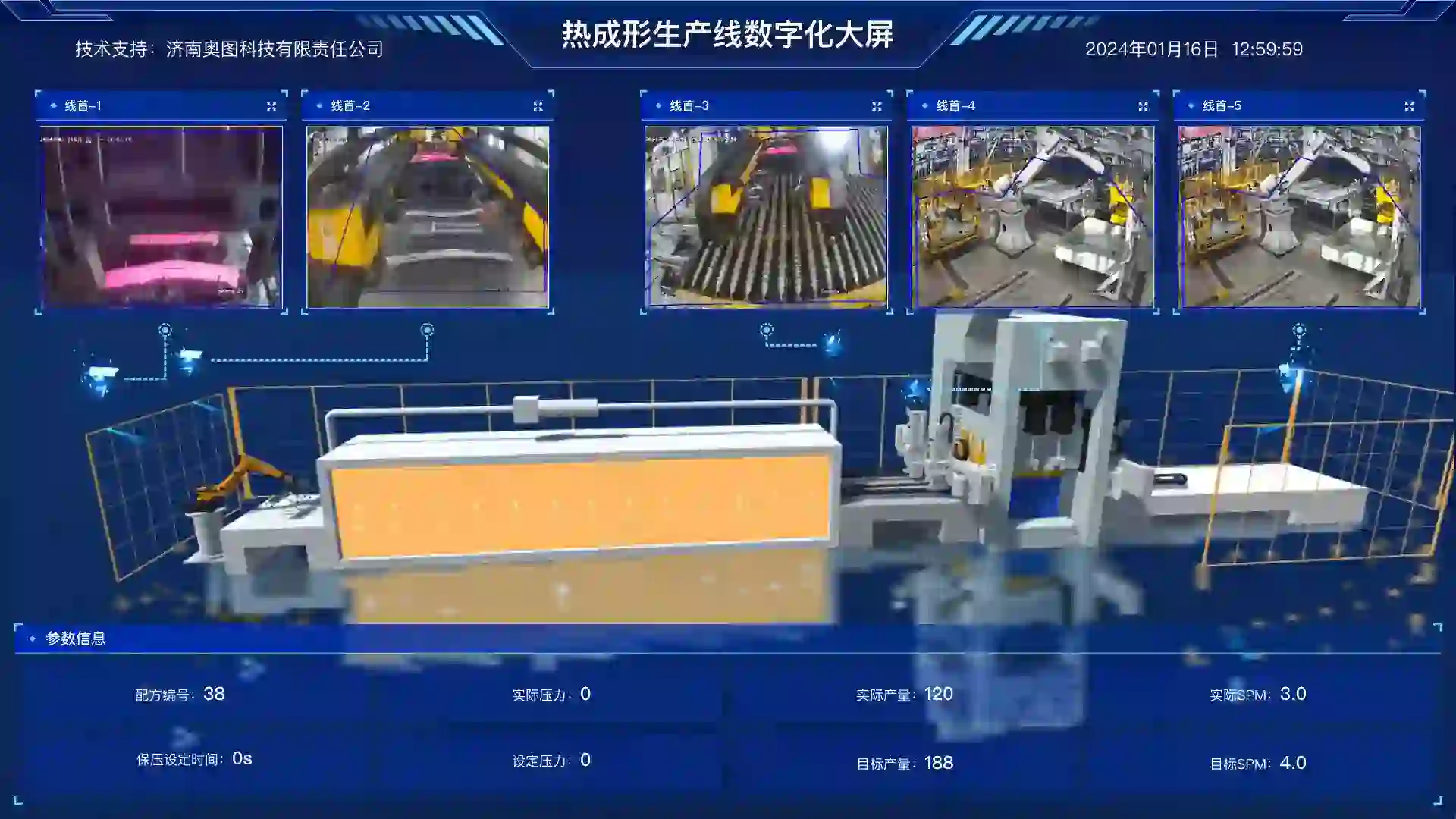

Electrical & Software Units

①Thermal imaging system

②Safety management system for die area

③Quality traceability

④MES system

Case view

Hot Stamping Line with Roller-hearth Furnace

Annual stroke up to 1,450,000.Delivered 150+ lines globally.

Hot Stamping Line with Chamber Furnace

1. Independent temperature control;

2. Multi-temperature zone design;

3. The furnace cavity can be enabled/disabled according to the production capacity;

4. Individually disassembled for easy maintenance;

5. Free of circulating water for oven rack cooling.

Visual Die Protection and Quality Traceability

Track the temperature of blank for both pre-forming and post-forming, Monitor the forming process and raise alarm when:1. Misallignment of blanks;

2. Double-blank;

3. Formed parts not taken out, etc.

Automatic Racking Solution

Fully automated finished part racking with robots and vision system.

Message box

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.