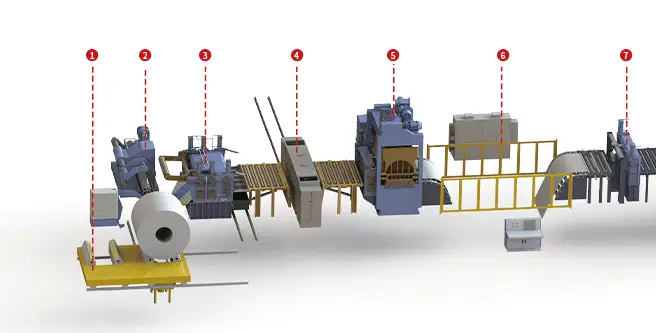

FOL: Decoiling and Leveling

①Blank preparation trolley: Prepare the coil to be processed

②Decoiler: Fix and support the coil and rotate to decoil

③Blank feeding machine: Drawing the blank strip into the subsequent equipment

④Special washer for coils: Remove the oil and particles on the surface of the blank

⑤Leveling machine: Flatten the blank strip, eliminate the internal stress

⑥Storing accumulator: Form the buffer U-bend of the blank strip

⑦Servo feeding machine: Accurately transferring the blank strip with laser blanking

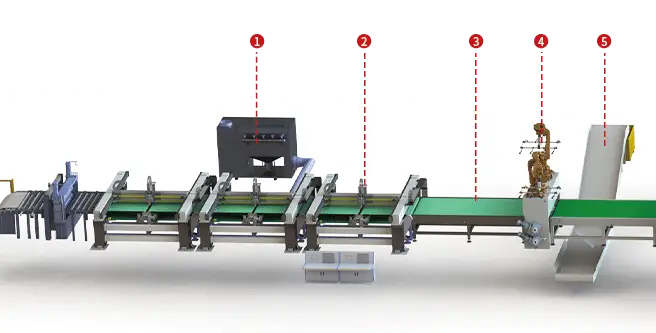

In-line:Cutting and sorting

①Cutting auxiliary machine: Laser, hiller, dust collector, etc

②Laser cutting machine: Supports the blank strip and utilizes the laser to cut the blank strip

③Transmission conveyor: Carrying the cut workpiece and the waste edges

④Sorting Robot: Grab the cut workpiece and send it to the subsequent cleaning and stacking part

⑤Scrap line: Collect and process the scrap edges

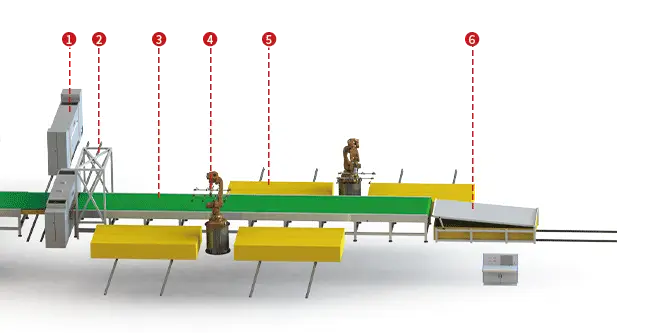

EOL: Cleaning and stacking

①Washer: Brusher and wet type, for cleaning the cut workpieces

②Visual centering: Recognize the position of the workpiece and guide the robot for gripping

③Unloading conveyor: Carrying and transferring the cleaned workpieces

④Stacking robot: Automatically grips the workpieces and stacks them on the trolley

⑤Stacking trolley: Work alternately, carry the stacks of materials and tap them neatly

⑥Scrap container: Containing scrap

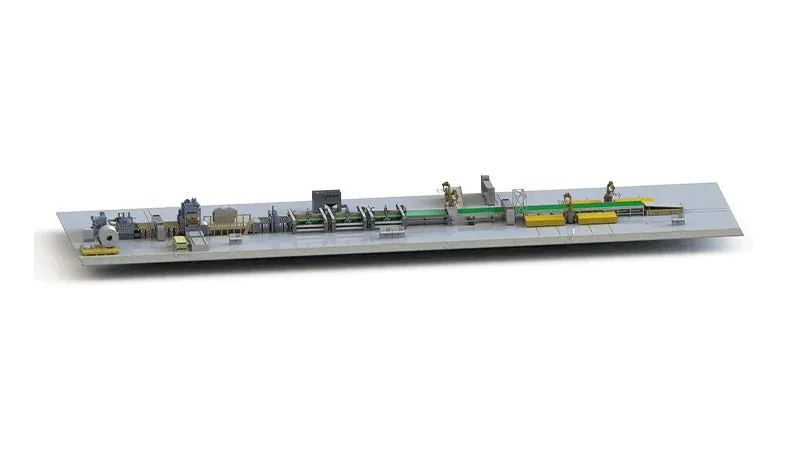

Laser Blanking Line for Exterior Parts

Laser Blanking Line for Hot Stamping Parts

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.