Aotto Supports Faway Benteler: Hot Forming Line Achieves 5.2 SPM

Aotto has supplied Faway-Benteler Automotive Components (Tianjin) Co., Ltd. with a hot forming line, enhancing production efficiency and product qualityto meet market demands and strengthen competitiveness.

Faway-Benteler (Tianjin), specializing in automotive components manufacturing, drawing on extensive industry experience and strong market reputation. The company introduces advanced technologies to strengthen production capacity and competitiveness, maintaining long-term partnerships with leading automotive manufacturers as a key supplier.

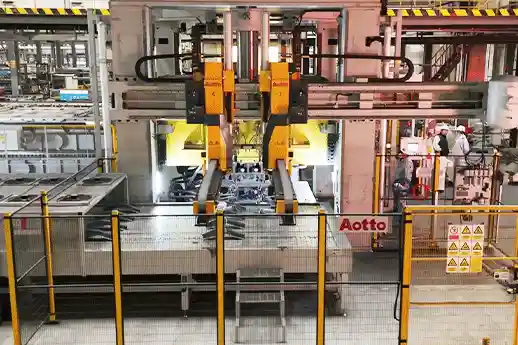

Hot forming unit

-

Six parts output one time: Efficiently utilizing space and resources to boost production efficiency.

-

FOL: Two destacking robot systems and two bi-directional servo marking systems, ensuring over 5 SPM.

-

Press Manipulator: 4.1m X-axis stroke for fast, stable blank handling in six-part output in one time.

-

Intelligent management: Implementing Awiz thermal imaging system and quality traceability system to collect the line parameters for predictive maintenance, guiding workpiece inspections and quality parameter settings.

-

The line achieved 5.2 SPM, demonstrating precise and efficient automation capabilities.

The collaboration includes comprehensive technical and service support. Aotto's team ensures responsive maintenance for stable line operation.

As Aotto's first collaboration with Faway-Benteler, the project received positive feedback on product quality and technical service. Aotto and Faway-Benteler will maintain close ties for joint innovation and mutual success.

Aotto will continue its customer-centric approach, prioritizing technological innovation and product leadership to deliver high-quality products and services, supporting the development of manufacturing globally.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.