Solution introduction

At the same time, many manufacturers have a great deal of potential in terms of rationalizing and streamlining their production of conventional cold-pressed parts. Here Aotto offers both new production equipment and automation of existing machinery and production lines – regardless of the make. For example, Aotto has automated a large number of tandem lines, which results in shorter cycle times, higher availability and improved product quality.

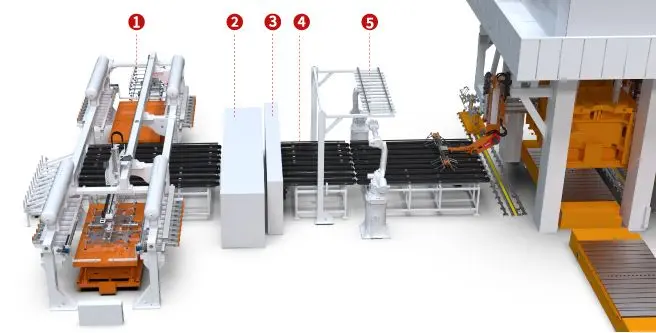

Structural display

FOL

①Destacking system: Separates stacks of blanks to single blanks.

②Sheet material washer: Clean the suface of the blanks.

③Blank oiler: Oiling process for steel panels with deep draw in the forming process.

④Belt conveyor: Transforming the blanks at FOL unit.

⑤Centering System: Centering and adjusting the blanks position.

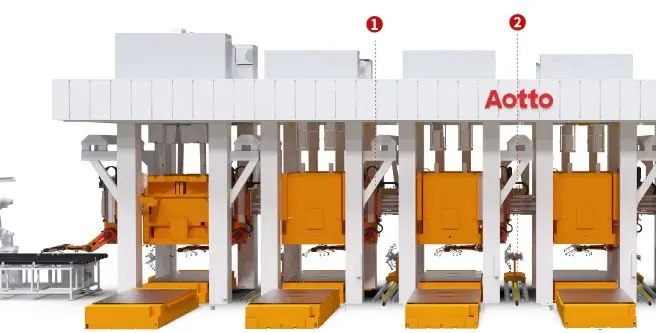

Inter-press Transfer

①Inter-press transfer: feeder/inter-press manipulator/unloading manipulator

②ATC: Automatic change of EOAT.

Case view

High speed stamping line with Aotto cross-bar feeder

Stroke: 15 SPM

Place of delivery: Anhui, China

Customers partition: OEM

Features:

Suitable for producing steel and aluminum sheets; The Aotto single-arm robot has 7 degrees of freedom and can meet the 15 SPM continuous mode production; Adaptable to a wider range of molds and compatible with all automated molds; Equipped with an ATC for automatic EOAT changes within 3 minutes.

Application with 7-axis robot

Stroke: 12 SPM

Place of delivery: Shandong, China

Customers partition: New Energy Vehicle Plant in China

Features: Suitable for producing steel and aluminum sheets; Equipped with Aotto 7-axle at the end position of the robot, it realizes translational transfer between presses; Equipped with Aotto washer and oiler; Capable of producing automotive exterior parts, up to 12 SPM in continuous mode; Equipped with an ATC for automatic EOAT changes within 3 minutes.

Application with 7-axis robot

Stroke: 13 SPM

Place of delivery: AnHui, China

Customers partition: Automotive Parts Supplier

Features: Equipped with carbon-fiber seven-axis robots, achieving 13 SPM, enabling full automation from destacking and transferring to racking.

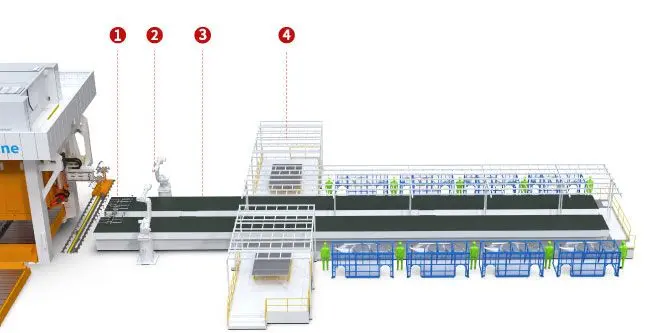

6-axis robot automatic stamping line

Application: automobile inner part press (medium size)

Stroke: 12 SPM

Features: 180° rotation transferring stamped parts inter presses;

FOL adopts magnetic separation and visual centering;

Employs Aotto's self-developed synchronization software to improve the stroke.

Message box

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.