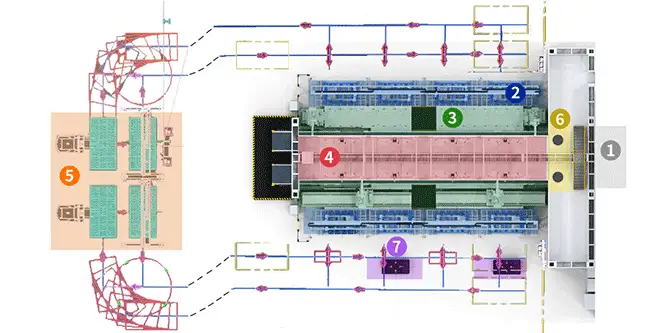

Equipment List

Equipment Advantages

Layout

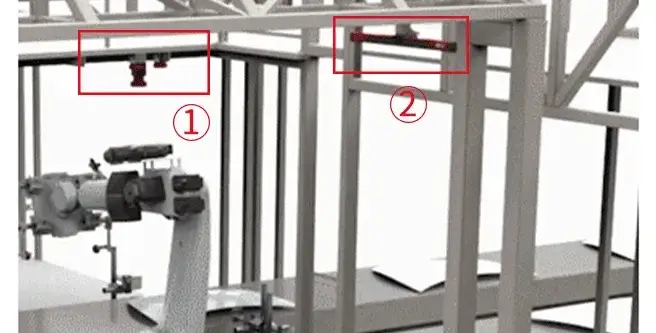

Racking (2D+3D camera positioning & guiding)

①Utilizing 2D camera for positioning and guiding the robot to pic kup the workpiece

Each group of robots is equipped with a 2D industrial camera installed above the conveyor, with special visual lighting protection area to prevent interference from external light sources;

Using 2D industrial cameras for guiding robots to pick up parts;

Upgrading existing conveyors to minimize costs.

②Utilizing 3D camera for positioning and guiding the robot to put the workpiece into the container

Using 3D visual camera to take pictures, with the camera installed above the rack, and there is a special visual lighting protection area to prevent the interference of external light sources;

Using professional picking software with a user-friendly interface for quick and intuitive operations;

Without precise positioning design for containers to minimize costs.

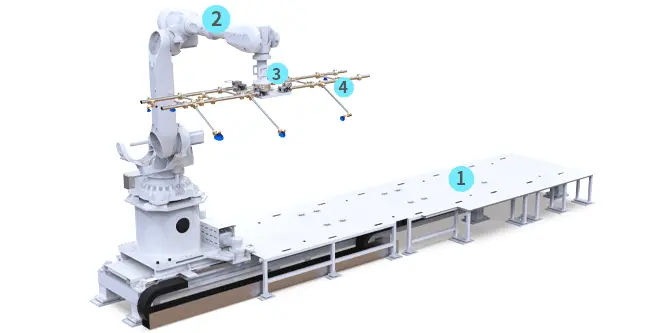

Robotics component

①Guided rails

Applicable to the racking of different workpieces and compatible with manual racking

②Robot

③Automatic tool changer

④EOAT

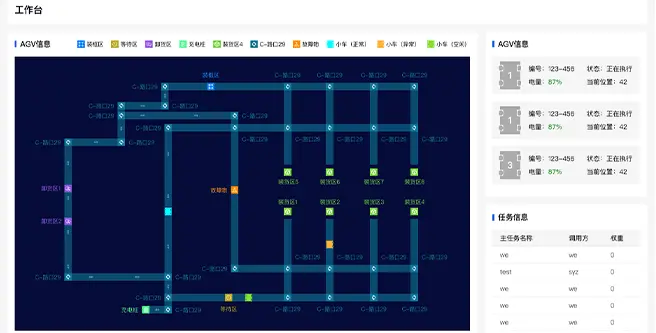

AGV & scheduling system

8+2 AGVs for the whole line

Towed or backpack type can be used according to the situation

360° free rotation

Automatic charging with 2-hour charge and up to 8-hour runtime

3-minute switchover

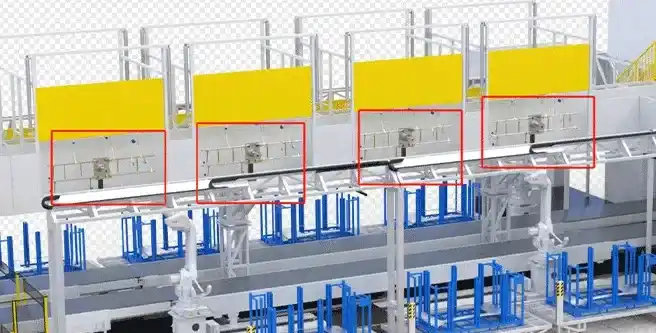

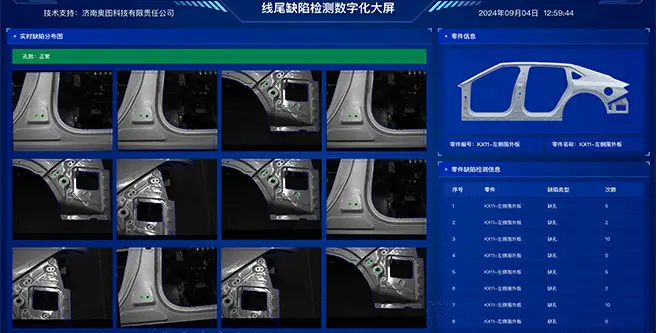

Quality inspection system for press shop

Pass-through inspection: Add inspection space above the conveyor to reduce the space requirement for remodeling;

Matching the stroke rate of 15spm, 100% inspection rate;

Compatible with over 99% of stamped parts of high-speed stamping lines;

Detection types: crack、scratch、missed hole.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.