Quality Inspection system for Press shop

The quality Inspection system for press shop utilizes a camera matrix combined with AI detection to replace manual visual inspections, enabling full inspection of products. This reduces the instability introduced by manual inspections and allows for uniform inspection standards across the board, reducing personnel usage and the probability of defective products leaving the production line.

Detection Program

Pass-through inspection: Add inspection space above the conveyor to reduce the space requirement for remodeling;

Matching the stroke rate of 15spm, 100% inspection rate;

Compatible with over 99% of stamped parts of high-speed stamping lines;

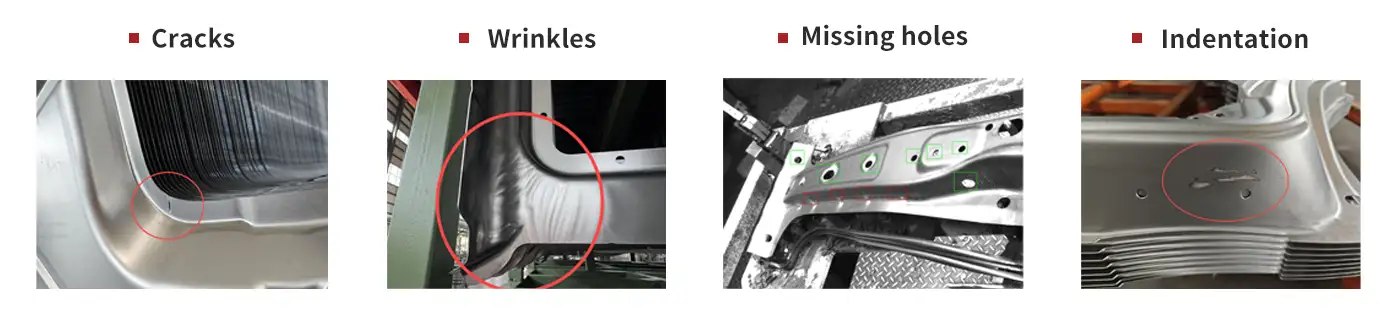

Detection types: Crack,Wrinkles,Missed hole,Indentation.

Cost Reduction

Reduced personnel usage leads to cost savings.

Decreased Defect Outflow Rate

Reduces the probability of defective products outflow by 50%.

Stability

Improves inspection stability by 50%.

Standardization

Uniform inspection standards improve overall vehicle quality.

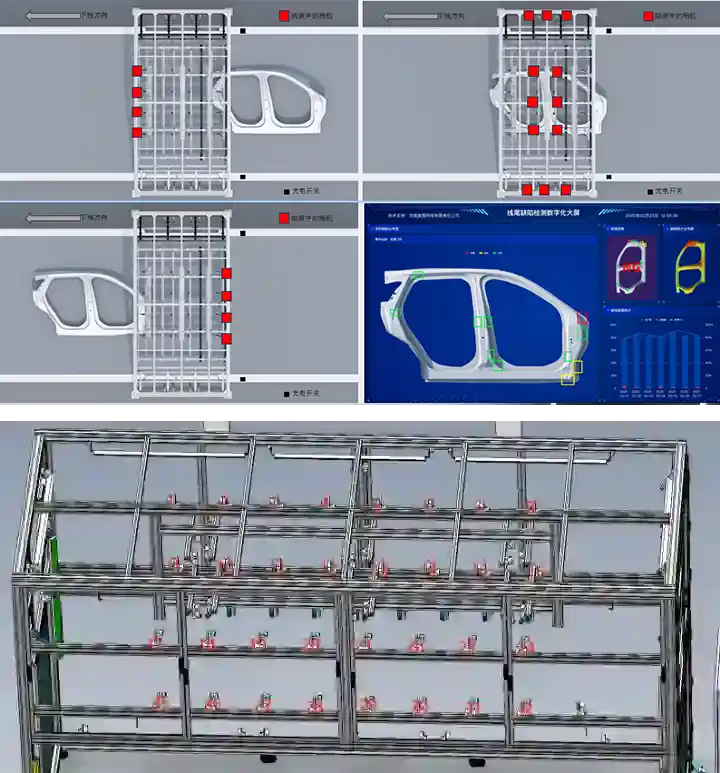

As shown in the diagram on the left, the Quality Inspection system for Press shop consists of enclosed inspection environments (which do not affect existing production line structures), computational centers, electrical controls, and human-machine interaction display platforms.

1、Enclosed Inspection Environment

By building a closed testing environment above the tail belt line of the stamping line, which does not affect the existing production line structure, different types of stamping parts can be uniformly imaged from all angles when passing through the closed testing environment, ensuring stable and reliable testing results;

2、Computational Center And Electrical Controls

Corresponding to the enclosed inspection environment are the cameras, light sources for image acquisition, and the computational servers for AI defect detection inference.

3、Human-Machine Interaction Display Platform

Provides real-time display of defect detection results for on-site manual review and feedback.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.