The integration of AI and digital twins helps businesses achieve predictive maintenance of their equipment. By establishing AI models based on PHM (Prognostics Health Management), the system can infer the probability of equipment failure based on the probability distribution of historical data. This predictive capability enables businesses to take preventive measures such as early detection and part replacement to reduce the probability of failure, thereby extending the equipment's usage and lifecycle.

Factory-Level Digital Twin

Digitizes the entire supply chain system, including aspects such as material procurement, transportation, inventory, and supplier management.

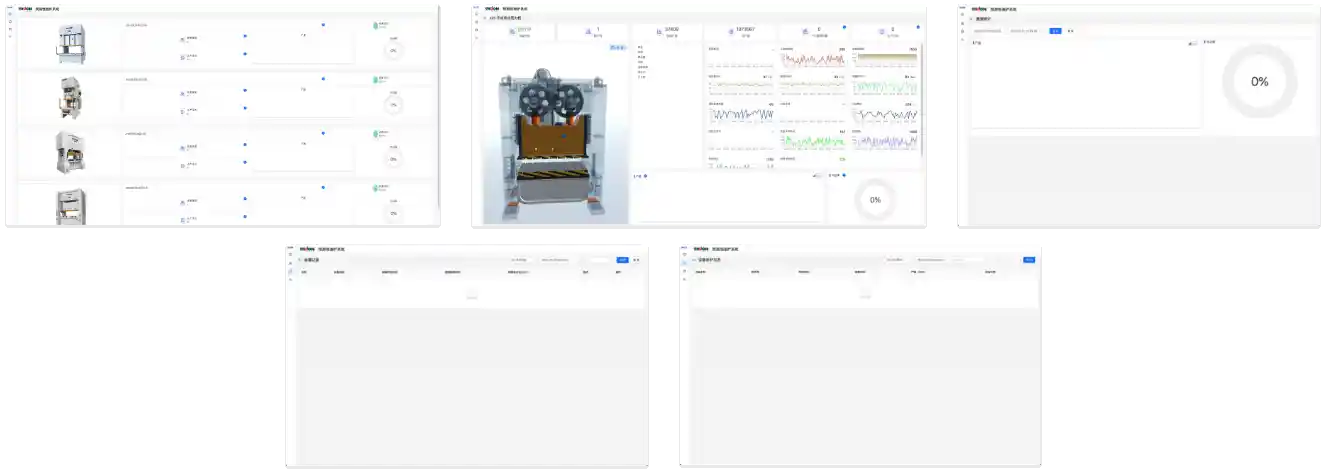

Workshop-Level Digital Twin

Digitally models manufacturing processes for real-time simulation and optimization to improve production efficiency and product quality.

Production Line-Level Digital Twin

Support for production line equipment monitoring, production process monitoring, and production data collection and other functions.

Workstation-Level Digital Twin

Support for workstation equipment monitoring, personnel monitoring, and production data collection and other functions.

1、Real-time Detection and Prediction

Digital twin technology can collect various data during equipment operation, such as temperature, pressure, vibration, etc., and transfer them to virtual models for analysis.

2、Online Performance Monitoring

Real-time monitoring of the production process to obtain performance data of products. Analysis of this data allows for understanding real-time changes in product performance, timely problem detection and resolution, thus improving production efficiency.

3、Equipment Failure Analysis and Prediction

Analyzes equipment operation data to detect abnormalities and predict possible failures. Once anomalies are detected, measures can be taken for maintenance and replacement to prevent equipment failures.

4、Optimization of Equipment Maintenance Plans

Develops more targeted maintenance plans based on the actual equipment status and operation conditions. By analyzing equipment health status and predicting failure risks, it accurately determines when maintenance is needed.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.