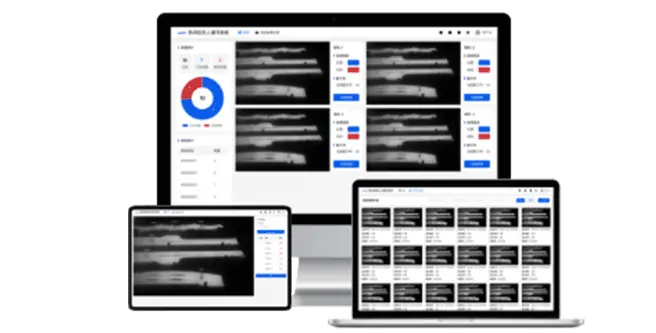

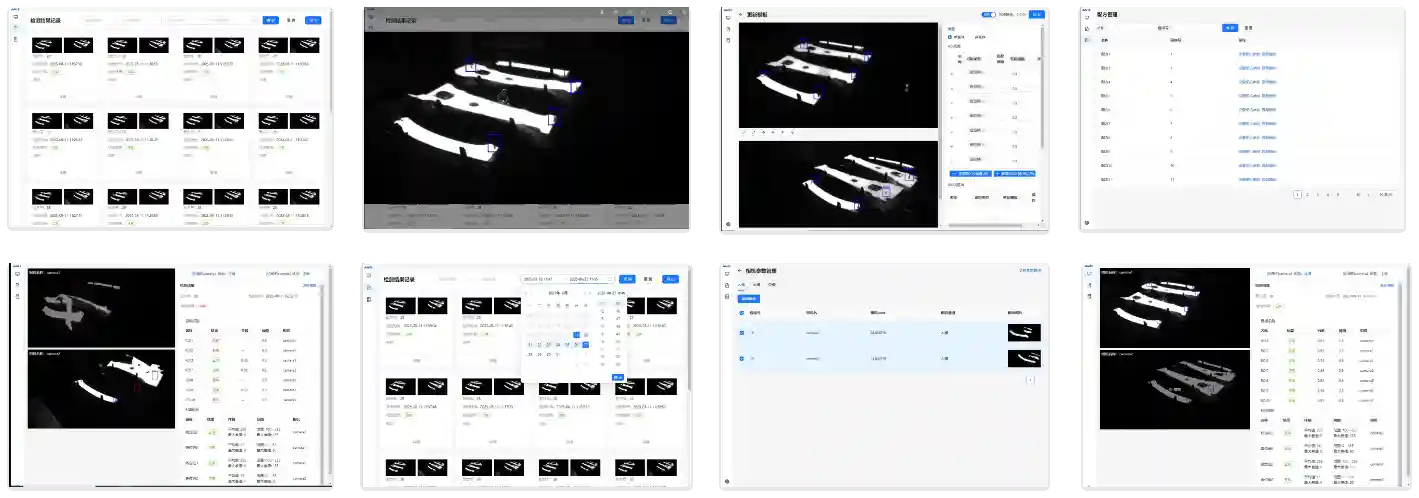

The hot stamping unattended system is a system that uses long-wave infrared cameras and short-wave infrared cameras, deep learning target detection technology and traditional image processing algorithms to achieve real-time detection of feeding and unloading conditions.

Any of the following situations will automatically trigger a shutdown without the need for human supervision:

Material misalignment or shortage in the die cavity before stamping.

Low temperature or double materials are detected in the die cavity before stamping.

Residual workpieces in the die cavity after stamping.

Unmanned

The system replaces personnel monitoring the production line for 24 hours.

Increased OEE

Reduced mould damage and unplanned downtime due to staff negligence.

High temperature long wave infrared camera detection

Short wave infrared camera detection

Low temperature long wave infrared camera detection

BYD

Changqing Corporation

Yifeng Group

Jiangsu Xincheng

VHST

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.