Aotto's Hot Forming Solution: Quality Inspection + Auto-Racking for Door Ring

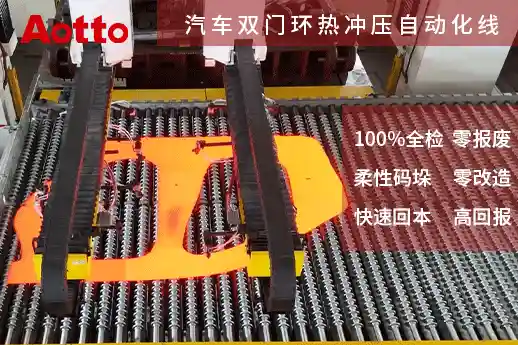

Recently, Aotto has successfully delivered a 2000T double door ring hot forming line for a leading automotive parts manufacturer. This line integrates a quality inspection system and automatic racking system, delivering a comprehensive hot forming solution.

Overview

Building on a standard production line, Aotto utilizes a shuttle cart to integrate door ring quality inspection and automatic racking functions into the hot forming unit. It can produce workpieces up to 3.2m x 2.5m, effectively catering to the full spectrum of market demands.

The line features a highly flexible design: the chain conveyor can handle both standard parts and serve as a sampling inspection passage for door rings. Additionally, the whole line is equipped with a bidirectional servo marking system at FOL and a visual die and quality traceability system, ensuring efficient and stable operation throughout the process.

Highlights: Intelligence & High Flexibility

1. 100% Inspection & Zero Scrap

In a dedicated darkroom designed to eliminate light interference, the door rings undergo 100% quality inspection. Upon detecting any defects, it immediately triggers a shutdown, preventing batch scrap.

2. Flexible Racking & No Modifications Required

The system supports both flat-lay and side-hanging racking modes for door rings. Leveraging 3D vision recognition, it seamlessly interfaces with customers' existing material frames without any modifications.

3. Forward-Thinking Design

The production line reserves AGV logistics interfaces, enabling seamless integration and intelligent transfer for future hot stamping and laser cutting processes.

Core Values

- Cost Savings

Automated inspection and racking save at least 4 operators, reducing long-term labor and management costs.

- Short ROI Cycle

With labor savings and zero scrap benefits, the production line offers a rapid return on investment, allowing customers to recoup costs in a short timeframe.

- Risk Control

100% inspection and real-time feedback prevent economic losses from batch quality issues, ensuring the reliability of automotive door ring production.

- Investment Protection

No modifications to material frames are needed, avoiding additional investments and maximizing the protection of existing assets.

Aotto is committed to hot forming automation, providing stable and reliable comprehensive solutions for automotive stamping.

Are you looking for something else? Please get in touch with Aotto, we are pleased to answer your request.